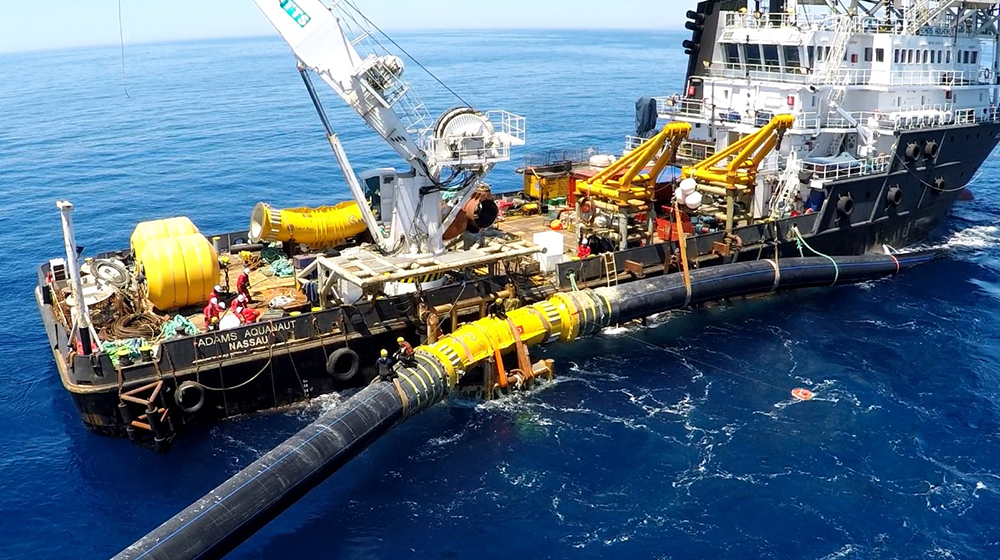

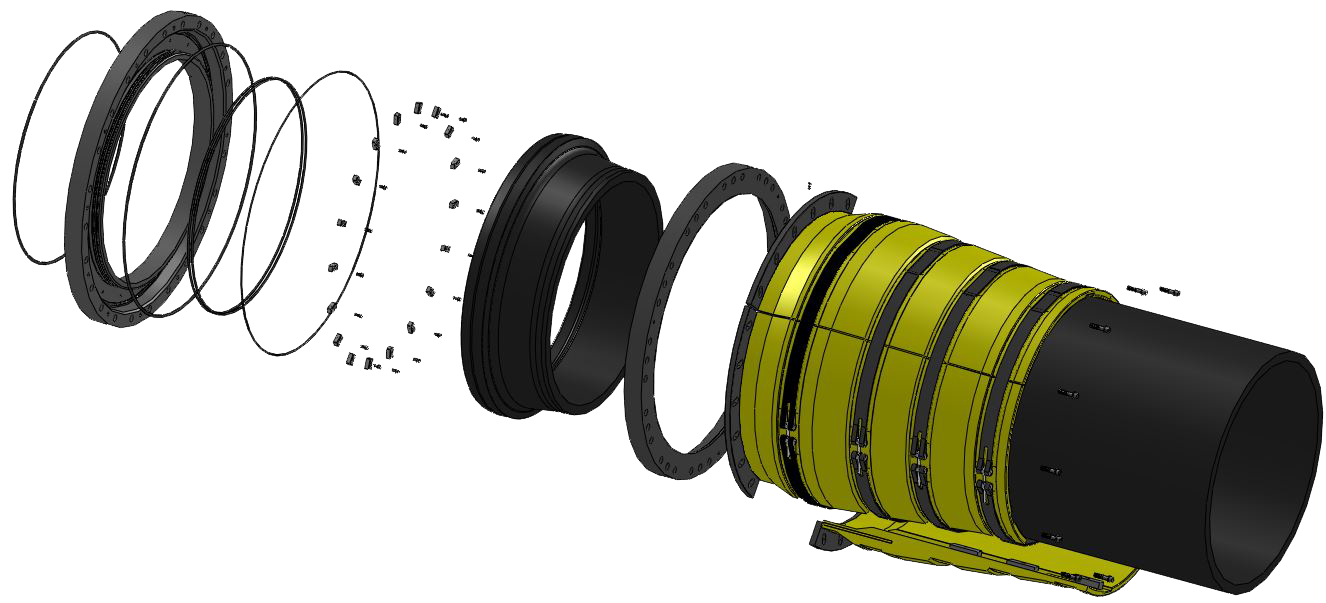

As part of the larger TRNC Project scope of work AES was also commissioned to produce a detailed design solution of the Steel to HDPE 100 pipe element joint that will support the potential limiting installation loads as well as ensuring leak proof water passage while subjected to the operational load cases for the life expectancy of the pipeline. The effort throughout the extensive Project has been focused on producing a cost effective and robust design solution considering the 268 joints assemblies to be fabricated assembled and delivered in a very aggressive timeline.

The arrangement and geometry of the unique joint solution has been optimized by AES engineers through extensive structural FEA analysis for the various load cases, lifetime change in material properties and dimensional sensitivity of the various elements.

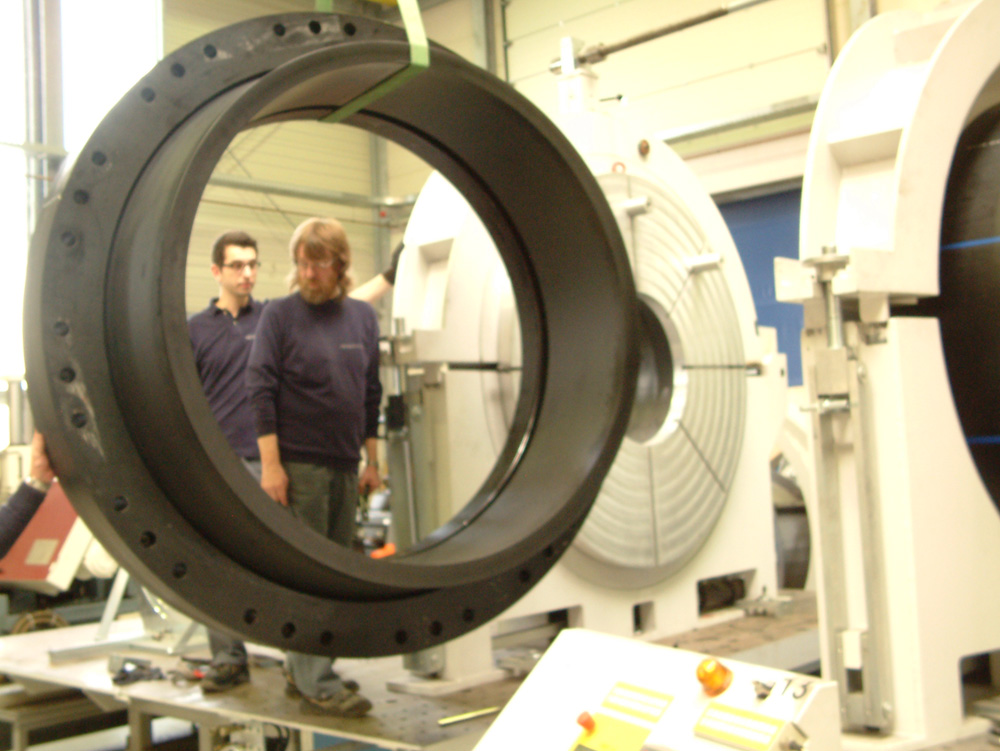

Latter, the design solution has been subjected to extensive load testing program to ensure the leak proof qualification and also to complete the ABS certification.

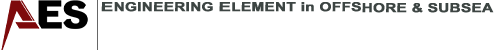

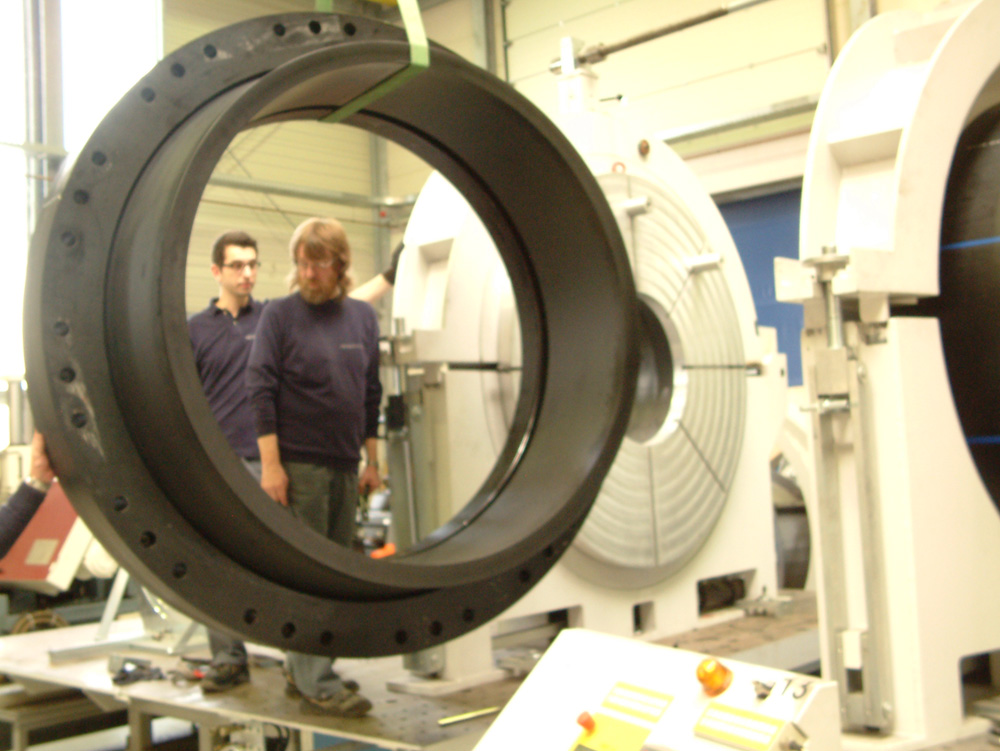

Connecting two reservoirs in Turkey and the TRNC sides, the 80 kilometer pipeline will set new standards in water supply and offshore construction technology.

CASE STUDY:

Bend Stiffeners,

Read More…..