310msw (1020fsw) Rated 170ton Piled Anchorage System PROJECT

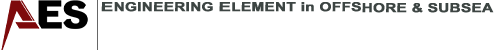

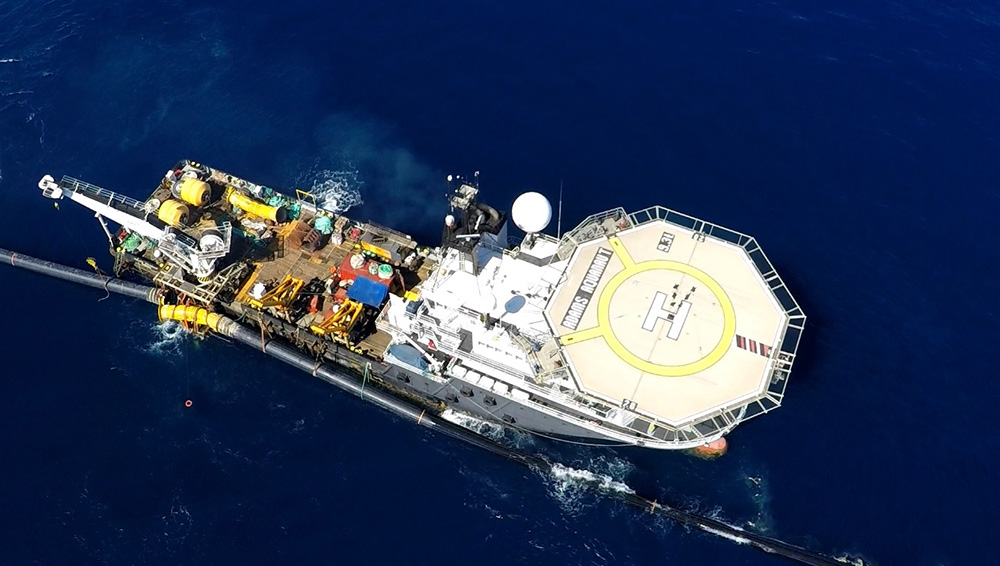

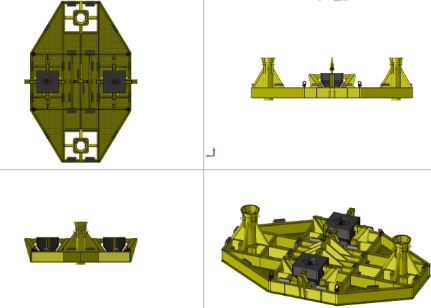

Delivered design and detailed engineering for four different types of 36m long vertically piled 170ton in air weight subsea transition anchorage structure.

The Piled Anchor Blocks (PABs) have operational water depths ranging from 280msw to 311msw and with subsea slopes ranging up to 17deg.

PABs are designed to include 40ton post installable weight blocks to keep the overall system in air weight within vessel crane capacity and also to increase the in water weight of the PABs during in-place operational conditions.

SCOPE

1. Project Management and Planning

2. Performance and requirements matrixes for static loads, dynamic loads, environmental, reliability, maintainability and install ability

3. Complete Detailed Design, Engineering & Fabrication Drawings including:

a. Develop Conceptual Designs.

b. Integration of Tether connections for the existing system components.

c. Integration of Remote Intervention for pile clamping solutions

d. Produce a Design Reports demonstrating compliance to all input load cases

i. Pile Sizing, Piling & Overturning Checks

ii. Bearing capacity & Foundation Optimization (API RP 2A WSD)

iii. Sliding Resistance Check (API RP 2A WSD)

iv. Anchor lift pad eye analysis

v. "Hydrodynamic load calculations

vi. Slam loads and added mass (DNV-RP-H103)

vii. Cathodic protection design (DNV RP B401 - 2010)

viii. Pile to anchor connection design

ix. Anchor overturning check

x. Structural Analysis

xi. Lifting Analysis

xii. Material Selection Report

xiii. Anchor on-bottom stability checks

xiv. Weight Analysis & Lifting CG and BG center

xv. Generate a full set of fabrication drawings

e. Fabrication Engineering Consultancy

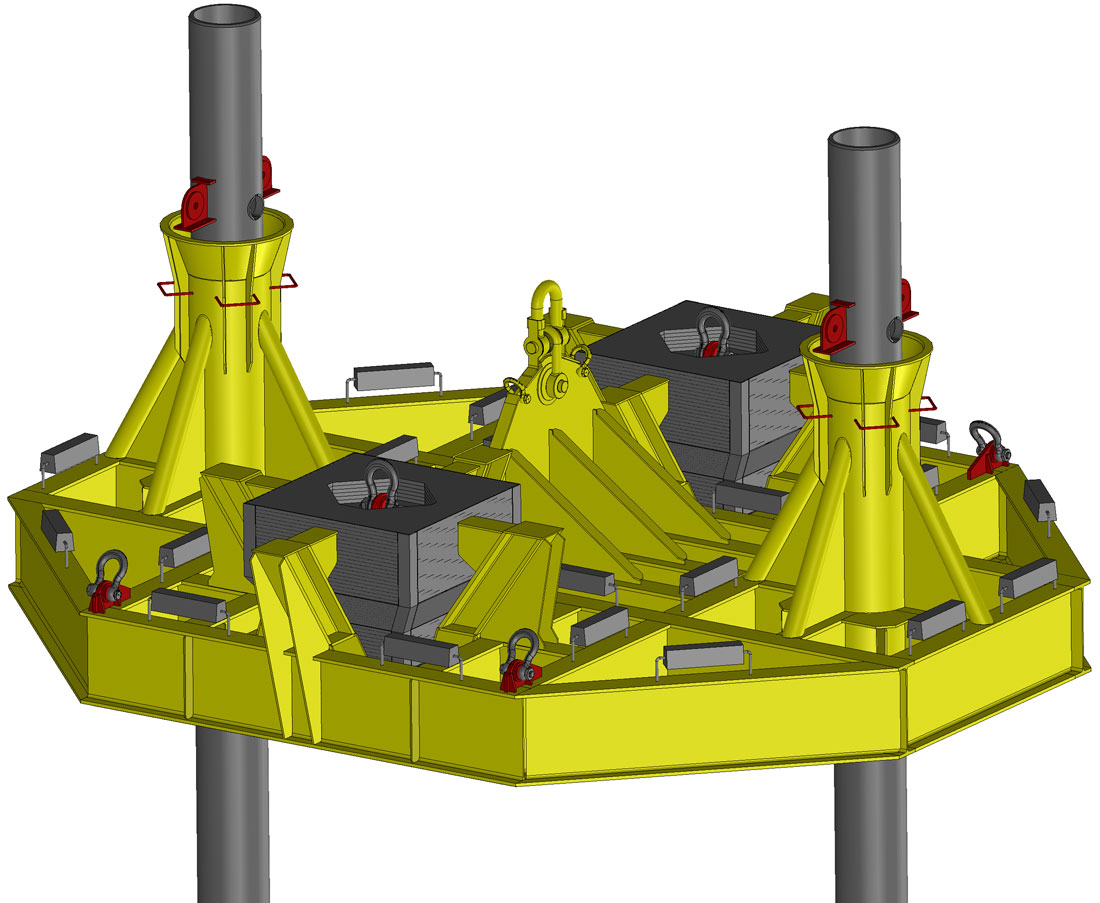

f. Offshore Installation Supervision from mobilization to final tie-in

Another successful engineering Project completion from the initial project plans to the finished product including the onsite installations, testing and commissioning phases to ensure the solutions are delivered with cost-effective, and highest quality service.

TRANSPORTATION

LAUNCH

INSTALLATION & PILING