A well designed piping system is designed with an eye for safety, construction, operation, maintenance and cost-effective solutions by AES in accordance with codes such as ASME B31.3 and ASME PVHO-1.

eXpertise:

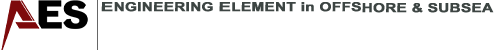

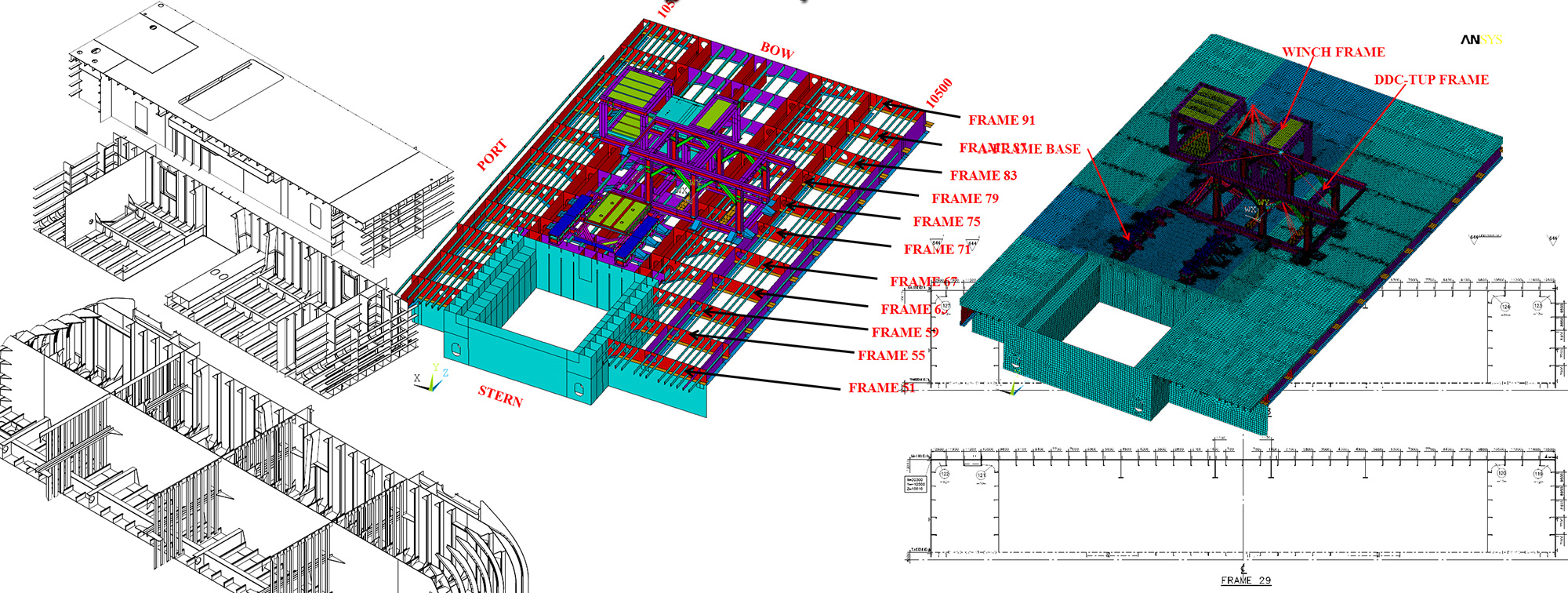

Seven (7) different 445psi rated Saturated Diving System projects put AES into a unique position with regard to pressure vessel design.

We have

vast experience within piping and layout design, including:

·

System Modelling

·

Compressible & Incompressible Pipe Flow

Network Analysis

·

Adiabatic, isothermal and generalized heat

transfer,

·

Pipe sizes, compressor/fan curves, valve

settings/selection, fluid properties, relief valve sizing and calculations

·

Piping flexibility analysis for offshore

installations, road & air transportation and for seismic loads

·

Layout engineering

·

Detailed design e.g. 3D modelling of piping and

supports

Some of our past piping

analysis and development of systems include but limited to

·

Pressurization of SAT System Chambers

o Mixed

Gas Supply

o Helium

Supply

o LP Air

·

Depressurization

·

Treatment Gas Supply

·

Oxygen Supply

·

BIBS Supply and Exhaust

·

Diver’s Supply

·

Gas Sample Lines

·

Cross Hatch Equalization

·

Tubing Wall Thickness and Burst Pressure

·

Diver Gas Reclaim System

·

Bilge Drain Piping

·

All Fluid Piping Systems (Sanitary and ECS)

·

Gas Storage Capacities

·

CO2 Removal Systems

·

Calibration Gas Systems

·

Over Pressure Protection

·

Hyperbaric Units & Chambers

·

Hypobaric Altitude Chambers

·

LNG Skids

·

Environmental Conditioning Units for Habitats

& Chambers