SYSTEMS ENGINEERING

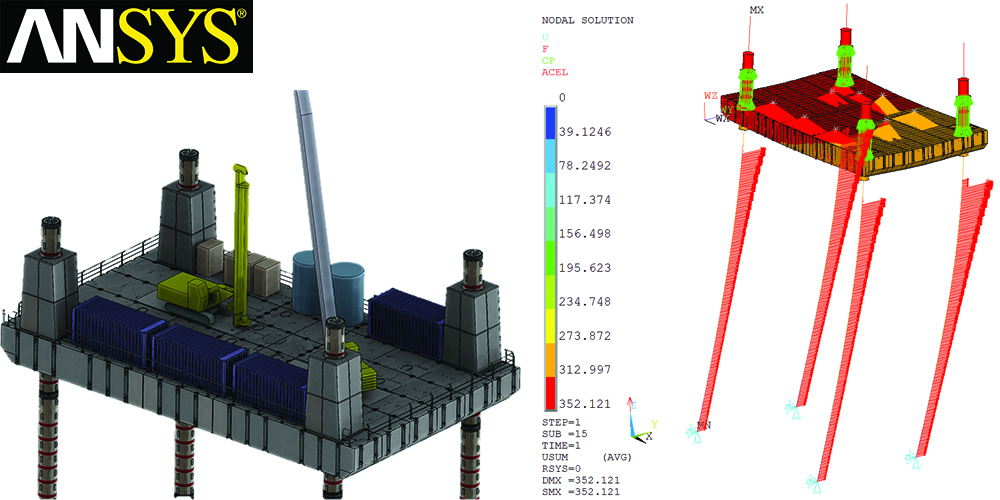

Any significant subsea production system is composed of many different elements that must be completed separately, but all of which must work together in harmony.

We use systems engineering to understand the desired capability, client’s objective and evolve the solution through various subsystems required to meet its required capability over the life of the system.

Dealing with complexity requires industry-based knowledge to develop an understanding of the interrelationships among the system components.

With our team members' 10o+ years of combined experience we manage very complex subsea problems by breaking them into manageable size and delivered many succesful projects to our Clients.

ADVANCED SUBSEA ENGINEERING

We execute successive research and innovation in our daily engineering tasks with a solid project track records from many different subsea and offshore installations and delivered systems.

From the initial project plans to the finished product including the onsite installations, testing and commissioning we ensure our engineering solutions are delivered with cost-effective, efficient and highest quality service.

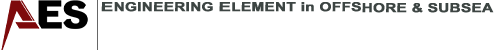

FABRICATION

AES provides its customers with a one-stop capability. We fabricate offshore and subsea products as part of our turnkey installation projects.

We also support our Client's supply chain with vendor selection, production readiness reviews, quality control ,scheduling and delivery.

AES has a global network of suppliers to provide fabrication, assembly and production testing services.

DNV & ABS Cerfication: All our offshore deployed systems to this date have been either ABS or DNV certified systems. With years of experience built from receiving production certifications for offshore's harsh enviromental requirements, we offer fast and cost efficient 3rd party certification services.

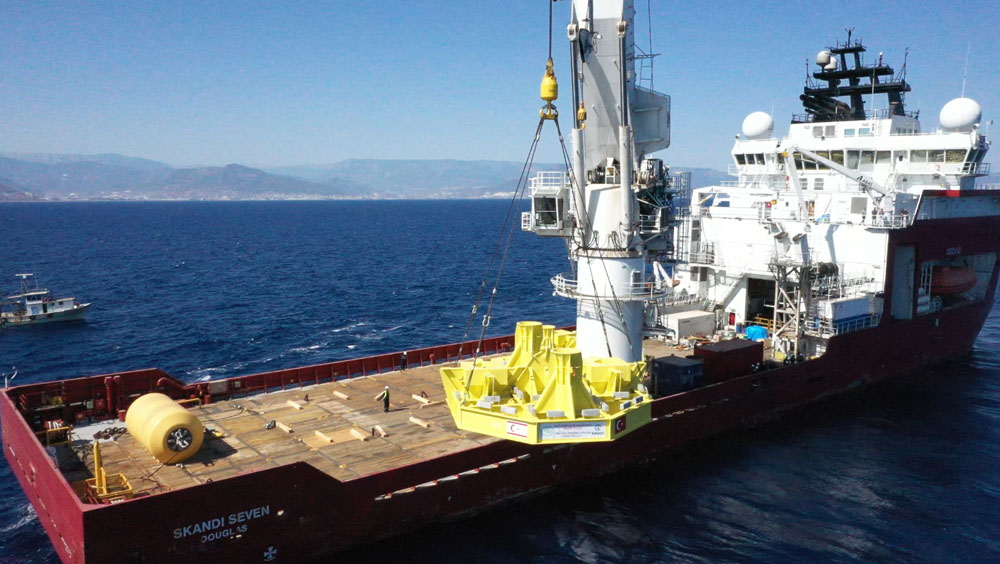

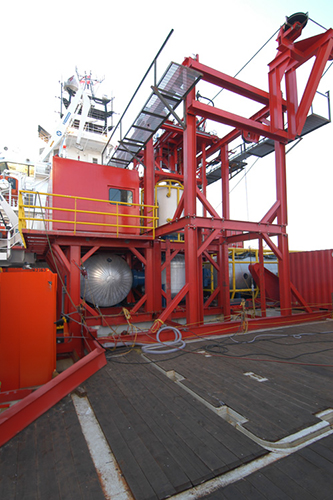

OFFSHORE CONSTRUCTION & INSTALLATION

AES' years of involvement with several challenging subsea projects has provided the Company with the absolute latest offshore technology for turnkey construction and installation services. This allows us to meet the deep-water project requirements in time, continuously advance AES' reliability.

We continue to operate throughout the World including Gulf of Mexico, U.S. and Middle East area, complet our subsea installation Projects as per scheduled milestones, safely, cost-effectively and successfully.

INSPECTION, SURVEY & MAINTENANCE

We provide complete management and performance of Offshore Inspection, Repair and Management (IRM) Projects.

Services are including but not limited with creation of technical documentation, functional and refined requirements, Method of Statements detailing operations, development of itemized equipment specifications, optimization of survey spreads for individual Job specific requirements.

Supervision of all key activities including mobilization, operations and demobilization of Equipment, Vessels and Crews with turkey scopes of scheduling and budget planning.

Completed succesfully TRNC IRM Services and Trans Anatolia Natural Gas Pipeline (TANAP) ROV & Survey Positioning Services

NAVAL & GOVERMENT PROGRAMS

Participation through several government projects has placed us in the unique position of possessing broad technical knowledge, programmatic experience, and a thorough understanding of the government and commercial project requirements involving significant technical challenges.

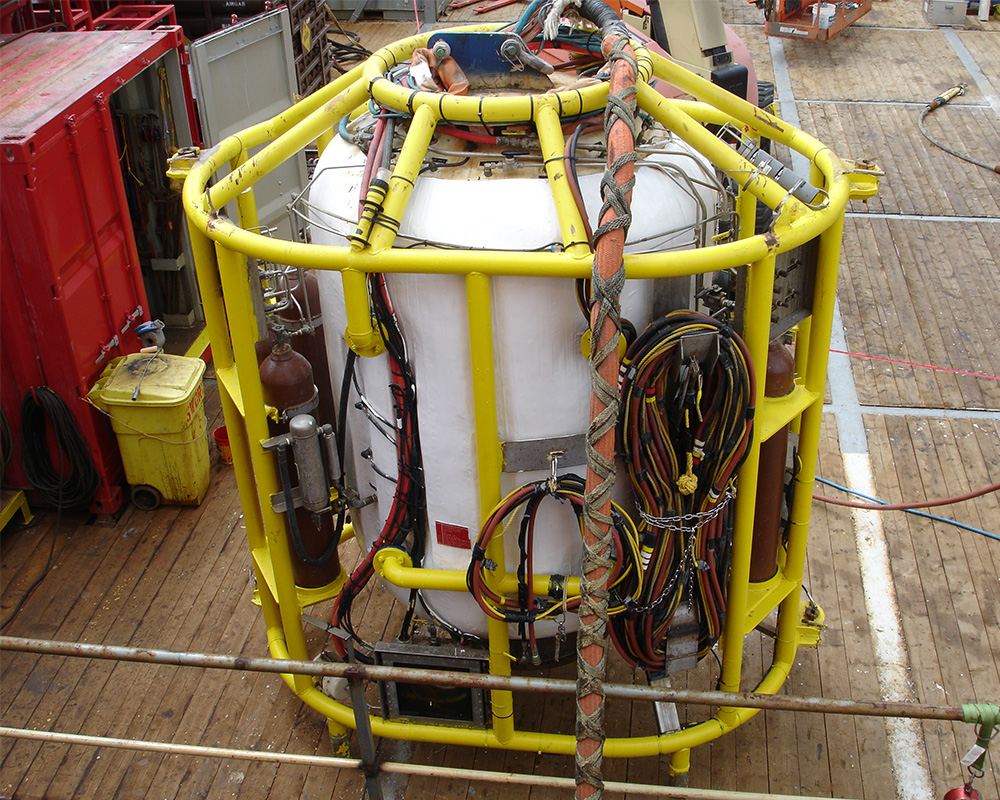

ROV SYSTEMS

Involvement with several Remotely Operated Vehicle (ROV) projects provided AES with the absolute latest in offshore technology to meet the deep-water project needs efficiently and cost-effectively.

Based on the unique requirements of the installation, we select, equip. mobilize and operate work class to observation class ROV systems to complete our services.

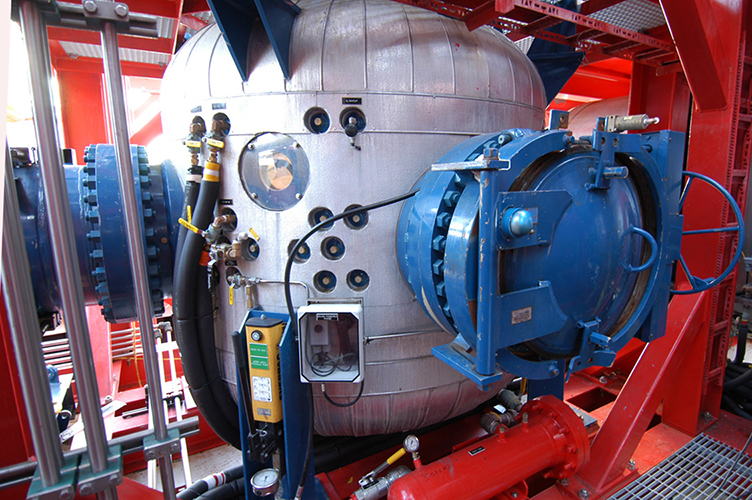

DIVING OPERATIONS & SERVICES

Subsea installations often requires diving operations from mixed gas diving to saturation. As per the requirements of the installation depth, operation to be executed and method of statements prepared by the AES engineers, we mobilize Diving equipment and Divers to have the products installed.

There are three core values of AES when we undertake a diving service or support work.

1- Firstly, we endeavor to hire, train and retain the highest quality and most efficient diving teams to support and perform diving operations.

2- Secondly, we form synergistic partnerships globally, so teams possess a combined skillsets with state of the art equipment and resources.

3- Finally, we utilize teams and partnerships with years of industry experience to deliver the highest quality, yet cost effective and reliable solutions and service to clients.

We have in house expertise for certified commercial Diving Systems including Saturated Diving & Stage Diving systems, Launch & Recovery systems.

We provide engineering for the modifications and certification of vessel interfaces on Vessel of Opportunity, deck layout planning, deck analysis, including ABS and DNV certification of sea-fastening analysis.