AES provides Pressure Vessel designs with

in-house engineering and extensive experience in design, analysis and

certification of vessels used in diving systems, refineries, chemical plants,

power plants, nuclear plants and other processing facilities.

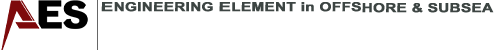

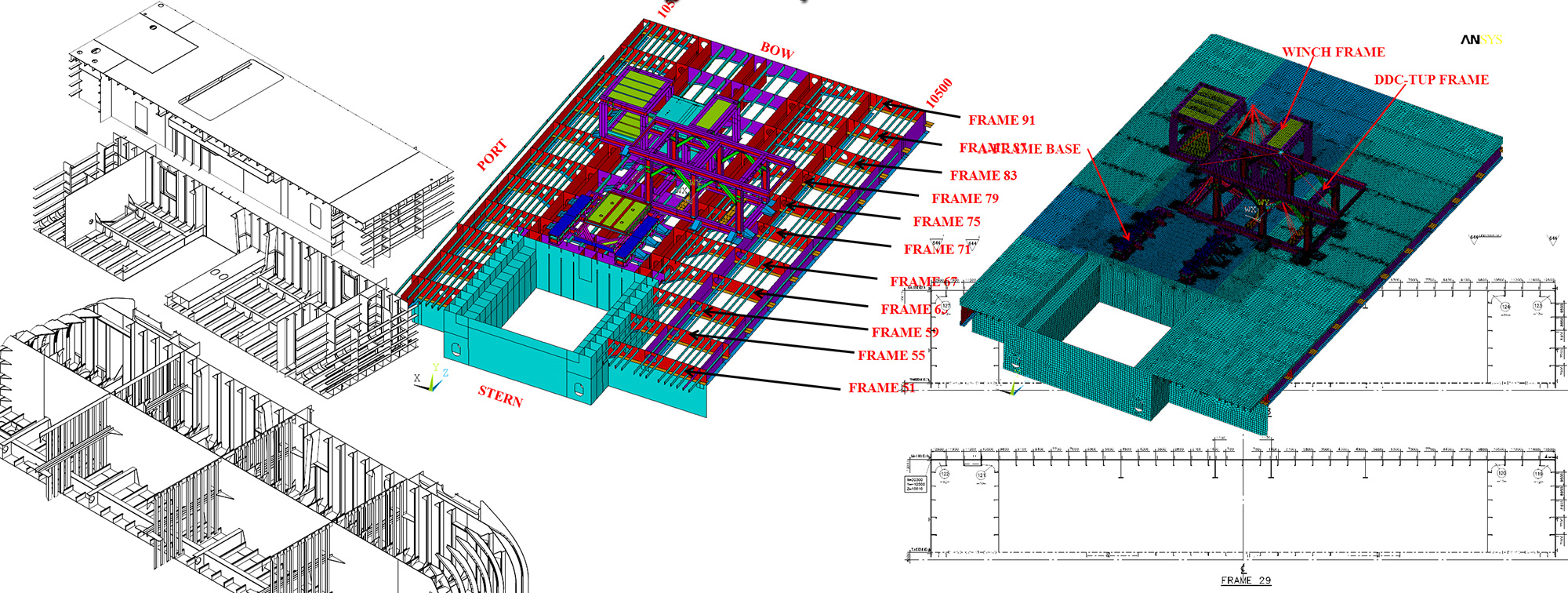

AES team have been appointed several Pressure Vessel for Human Occupancy (PVHO) projects and also have been involved with vertical and horizontal process vessels such as separators that are used in the Oil Treatment applications with the capability of handling large slugs of liquid.

eXpertise:

Seven (7) different 445psi rated Saturated Diving System projects put AES into a unique position with regard to pressure vessel design.

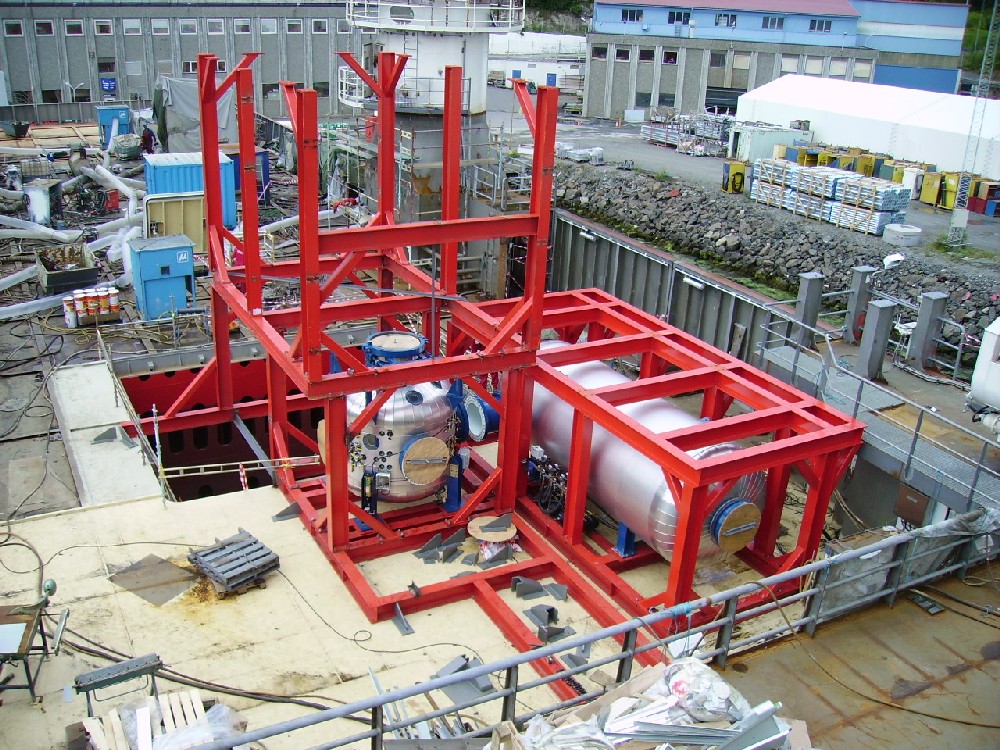

Pressure Vessels deployed to Oil Rigs and

mobilized on Diving Support Vessels require to be designed with additional

design loads in order to survive the transit, operational and non-operational

conditions under maximum operating pressure. Such pressure vessel designs for

human occupancy specifically designed for offshore operations account for the

mating vessel loads, such as punch, tension, bending and torsion loads in

addition to the dynamic accelerations of the supply vessel. Design

AES completed seven (7) different 445psi rated

Saturated Diving System projects which puts us into a unique position to design

pressure vessels for offshore applications. The challenge with such projects is

not to meet the ASME Section VIII rules only but also to meet the rules of ABS

Underwater Vehicle, Systems and Hyperbaric Facilities rules for the external

mating and dynamic acceleration loads of harsh offshore vessel operations in

Sea State 5 and above conditions.

With years of practical work in the industry, AES offers solutions for pressure vessel projects that have mission critic requirements.

Using the state of the art Coadware

Compress, ANSYS FEA and hand calculations in accordance with ASME Section VIII Div 1 & 2 rules AES has delivered several pressure

vessel projects for

1. Tall

Columns,

2. Vertical

Pressure Vessels,

3. Horizontal

Pressure Vessels,

4. Spherical

Vessels,

5. Heat

Exchangers,

6. Filters

We have experience in designing

pressure vessels in accordance with

1. ASME

Boiler & Pressure Vessel Code, Section VIII, Div. - 1, Div. - 2 and Div. –

3,

2. ASME I -

Construction of Power Boilers

3. ASME II

- Materials

4. ASME III

- Construction of Nuclear Facility Components

5. ASME IV

- Construction of Heating Boilers

6. ASME

VIII-1 / VIII-2 - Construction of Pressure Vessels