SUBSEA FIBEROPTIC CABLE INSTALLATION

BACKGROUND:

The Silivri Underground Gas Storage Facilities in the depleted gas fields of Kuzey Marmara and Değirmenköy have been successfully operated by Türkiye Petrolleri A.O (TPAO) since April 2007. In September 2016, Petroleum Pipeline Corporation (BOTAŞ) took over the existing Silivri Underground Gas Storage Facilities from the TPAO, including the Kuzey Marmara Underground Gas Storage Expansion (Phase III) Project.

Due to Turkey’s need for more gas storage capacity and recently discovered additional available working gas capacity in the Kuzey Marmara reservoir, the Kuzey Marmara Underground Gas Storage Expansion (Phase III) Project is being developed to increase the injection and withdrawal capacity.

AES has been awarded a 4.2km long two 95mm OD, 24 Core subsea composite cable (SCC) installation contract.

Installation engineering was developed in accordance with DNV and have received DNV Certificate of Approval (COA) for the method of statement (MOS). All construction and installation works were executed under DNV survey.

- Provision of the SCC cable lay analysis required for the completion of the Works;

- Development of detailed DNV procedures for all activities which form part of the Works;

- Receipt of DNV Certificate of Approval (COA) and all engineering communications

- Mobilization of offshore cable lay and trenching equipment

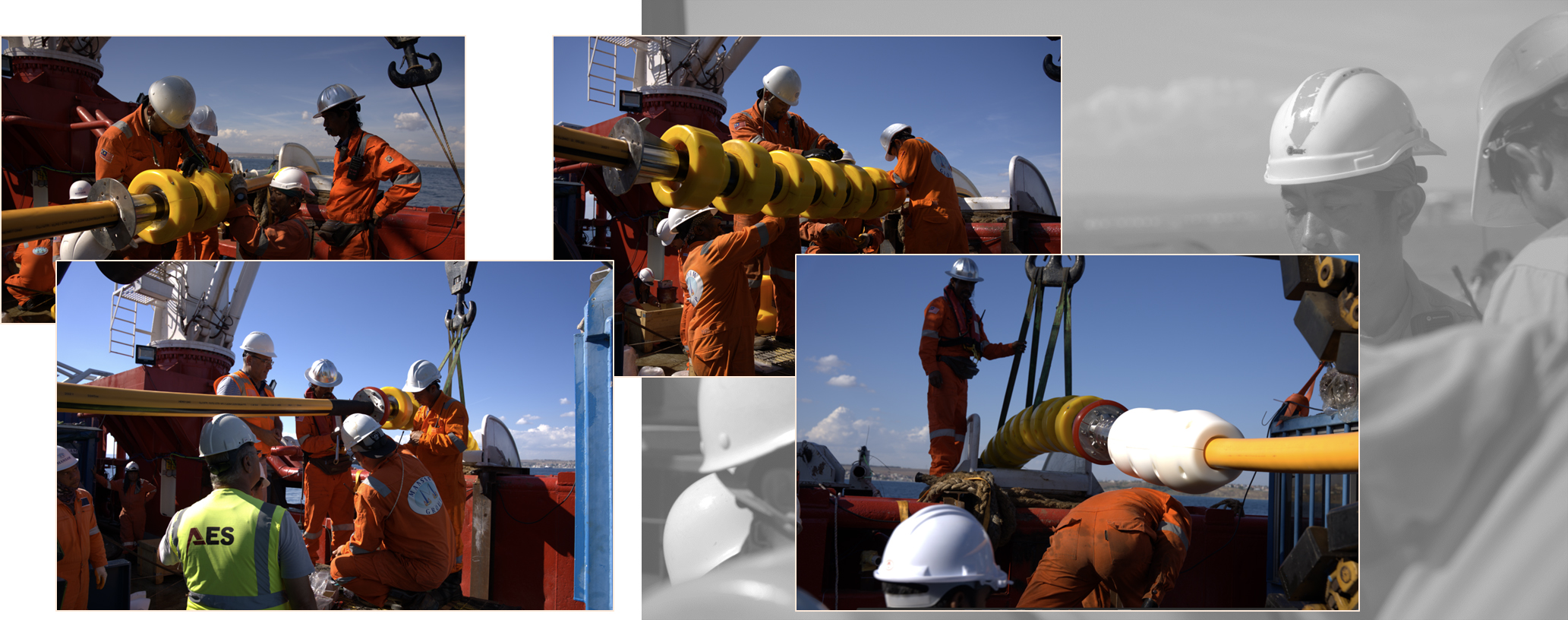

- Installation works of two (2) Submarine Composite Cable including onshore cable pull and J-tube pull operation at onshore and platform respectively

- Burial of two (2) Submarine Composite Cable including as-trench position and depth of burial as recorded during trenching operation by the DGPS positioning & USBL system provided and stinger depth sensor

- Termination and testing of two (2) powerline

- Termination and testing of fiber optic line

- Demobilization of offshore cable lay and trenching equipment

We are proud to sucessfully complete this challenging subsea cable installation Project.

Cable shore pull preperations

Cable Bend Restrictor Installation before the J-tube pull

Cable shore approach subsea trenching works