spool INSTAllation & SUBSEA tiE-INs for dp-1 & Dp-2 Offshore GAS Platforms

BACKGROUND:

The Silivri Underground Gas Storage Facilities in the depleted gas fields of Kuzey Marmara and Değirmenköy have been successfully operated by Türkiye Petrolleri A.O (TPAO) since April 2007. In September 2016, Petroleum Pipeline Corporation (BOTAŞ) took over the existing Silivri Underground Gas Storage Facilities from the TPAO, including the Kuzey Marmara Underground Gas Storage Expansion (Phase III) Project.

Due to Turkey’s need for more gas storage capacity and recently discovered additional available working gas capacity in the Kuzey Marmara reservoir, the Kuzey Marmara Underground Gas Storage Expansion (Phase III) Project is being developed to increase the injection and withdrawal capacity.

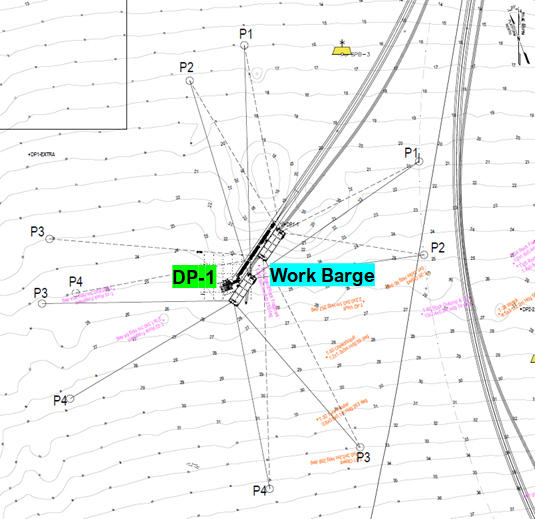

The pipeline tie-in is made by a flanged spool piece with a swivel joint, which fits the distance between the pipeline end flange and the riser bottom flange. To accommodate longitudinal movements of the pipeline end due to temperature and pressure variations the spool piece includes an expansion supplied by the Client.

AES was contracted to perform detailed engineering, develop installation procedures, acquire DNV approval and to install the spools for DP-1 at 25msw and for Dp-2 at 45msw depths.

AES has been awarded another contract for the detailed spool installation and tie-in engineering in accordance with the DNV F101 and for the turnkey installation services of 28” in diameter 50m long spools and 2-3/8” piggyback air and methanol pipelines. The turnkey engineering and installation contract was for the two offshore drilling platforms of Kuzey Marmara Underground Gas Storage Expansion (Phase III).

AES performed the detailed spool installation and tie in engineering in accordance with the DNV F101 to demonstrate that the sea fastening, lifting, submerging, installation, and tie-in steps will be within the allowable definitions of the applicable DNV regulations and will not overstress the pipeline and spool pieces.

The detailed engineering and FEA analysis were provided for each operational steps to ensure no damage will occur under operating limit conditions. DNV-RPH103 was used as the recommended practice for modelling and analysis of offshore lifting operations.

- Review installation methodology options

- Review vessel availability and technical specifications

- Develop a Vessel Matrix

- Develop installation methodology considering the available vessels in the region.

- Development of detailed spool installation and tie in engineering procedures in accordance with DNV F101 and DNV-RPH103 including design and production of all on deck and subsea installation spreads.

- Receipt of DNV Certificate of Approval (COA) and all engineering communications

- Mobilisation of offshore tie-in spool installation spread equipment and all associated personnel to manage and operate all offshore provided equipment including supporting spreads such as lifting, diving, ROV, survey spreads and excluding any Marine Vessels (DP2 Vessels), Crew Transfer Boats and Diving Boats and Fuels.

- Installation and tie-in of 28” 50m long spools and two 2-3/8” Air & Methanol instrument pipelines

- Installation and tie-in of expansion joints (Z and L spools) between the Riser and DP drilling platform

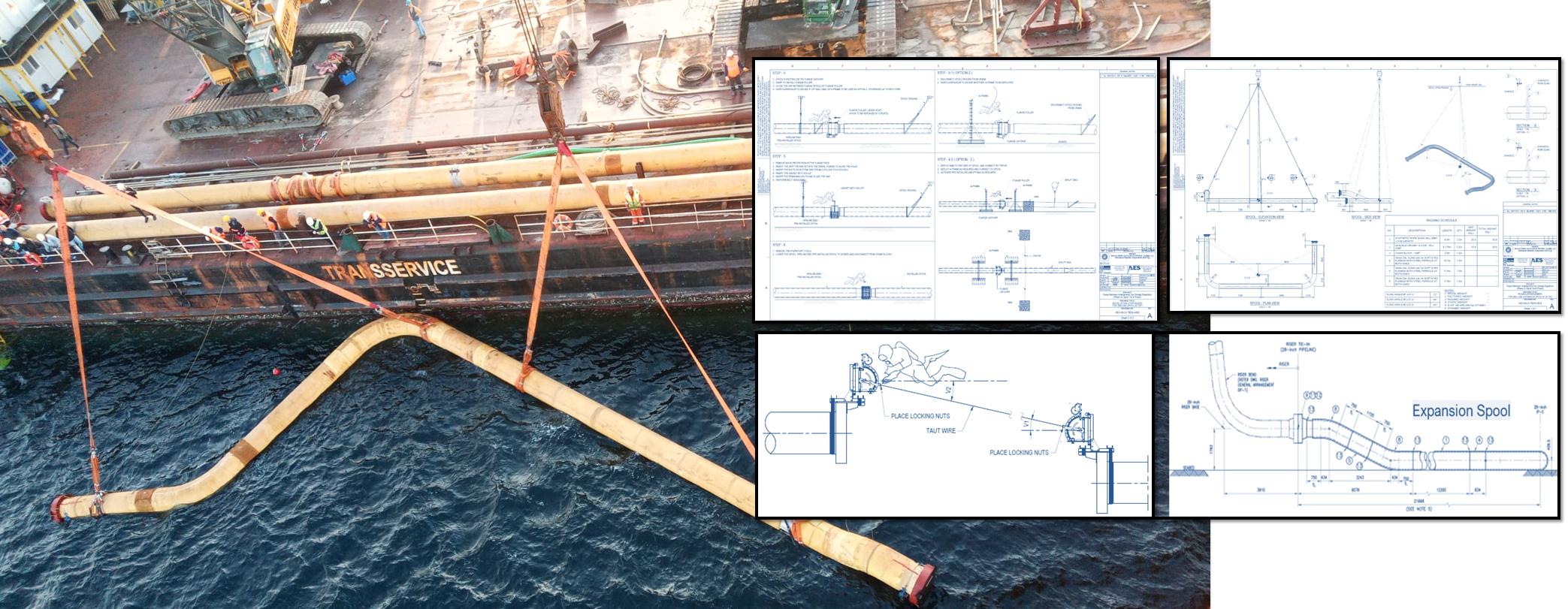

AES performed feasibility studies, detailed engineering and developed subsea installation tooling for a DNV approved tie-in procedure.

We are proud to sucessfully complete the challenging subsea spool installation engineering and tie-in project.

28" Z Spool Deployment for Riser tie-in at 45msw depth

Relentless offshore work around the clock