Turkish Republic Northern Cypress Fresh Water Supply Pipeline project is world’s longest and one of the most challenging undersea water pipeline project to bring freshwater from Turkey beneath the Mediterranean to northern Cyprus. A solution has been studied for more than 15 years and approved by the Turkish Water Authority (DSI).

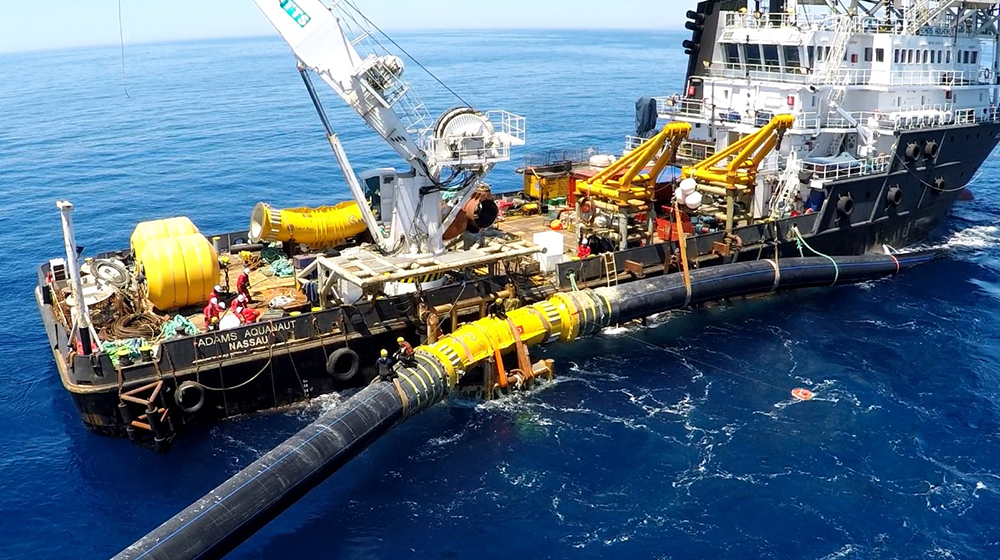

AES was awarded for the remaining effort relates to the detailed design, detailed engineering, prototype fabrication, full scale design verification and ABS certification services for the development of Y-Piece and Steel to HDPE joints. In addition AES has performed the overall global fabrication management, logistics and scheduling for various components of the system.

The in-house knowledge and understanding of the industry was essential to ensure successful completion of the aggressive timeline and challenging Project requirement.

AES team’s participation through several government and commercial development projects has placed us in the unique position of possessing broad technical knowledge, programmatic experience, and a thorough understanding of the various project requirements involving significant technical challenges.

PROJECT Summary

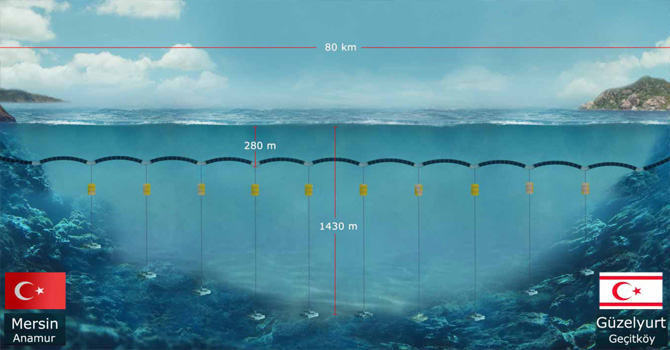

The project calls for Turkey to transfer 75 million cubic meters, or 19.8 billion gallons, of water a year to Northern Cyprus.

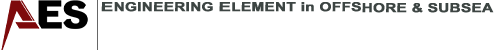

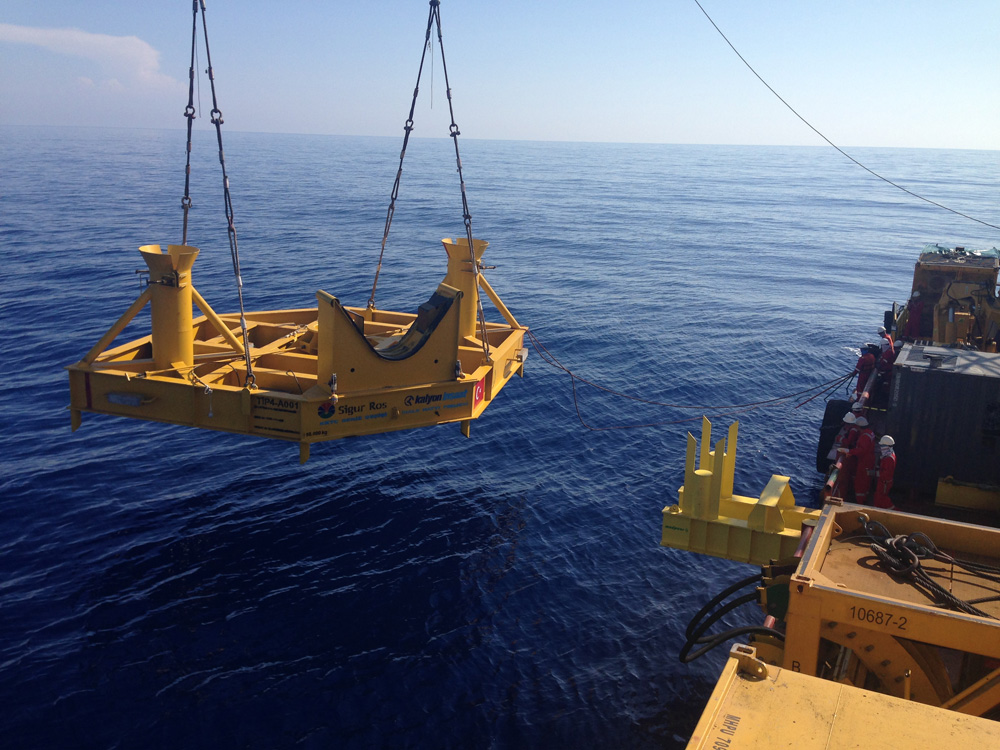

The pipeline diameter is 1600mm and traverses water depths of up to 1430m (4690f) below the surface of the Mediterranean which is one of the main challenges in the Project. The seabed installation was not applicable for this project due to the depth and numerous underwater ridges and trenches, exists along the installation route.

AES performs challenging scopes in the ambitious transnational fresh water pipeline project.

The pipeline material is High Density Polyethylene (HDPE) 100, which is commonly applied for water transportation systems. The basic concept involves a festooned pipeline at 250m (820ft) water depth in spans of 500m (1640 ft) length each. Adjacent spans are mechanically joined at the steel connector piece which is tethered to the seabed anchor. There are 132 steel connectors each with 2 steel to HPDE joints on both ends.

PROJECT HISTORY:

The plans for this project go back more than fifteen years. The Alaköprü dam at the Turkish side was planned as early as 1998; the installation of the PE 100 pressure pipeline is now merely the conclusion of a long chain of events. Construction of the dam began in the mountains of the province, to the north-east of the Mediterranean town of Anamur, in 2011. The dam is also to be used for the generation of hydroelectric power, as well as storing the water required for the pipeline. From the Alaköprü dam, the water is transported by pipeline to the Anamur pumping station, and then enters the pressure PE line leading into the Mediterranean. After travelling around 80 km through the sea, the PE pressure pipeline reaches the coast of the Turkish Republic of Northern Cyprus, where the water is pumped.

NOVEL APPROACH IN OFFSHORE & SUBSEA CONSTRUCTION:

The project represents a novel approach for offshore pipelines and the concept has been subjected to a detailed analysis and evaluation effort in prior years by various Turkish European Companies and by DSI, including an analysis of the global dynamic behavior of the overall pipeline. Based on this effort the concept and preliminary solution was approved by DSI for continued development.

Bend Stiffeners,

Read More…..

ABS 3rd Party Certification,

Read More…..